![]() +971552579247 | Call Us: +971559994937

+971552579247 | Call Us: +971559994937

Cable Blowing Machine – A Guide For Choosing The Right One And Using It Rightly

Cable Blowing Machine – A Guide For Choosing The Right One And Using It Rightly

Do you have an overall idea about a cable-blowing machine? Not many have a clear idea about the machine or its functioning ways. It is impossible to comprehend everything related to the machine unless you are part of the telecom industry. Other than telecom, any network-based industry using optical signals as the transmission necessitates the application of cable-blowing machines. Read on and get to know many vital aspects about the machines and their utility to ease the purchase decisions.

A brief outline of the machine

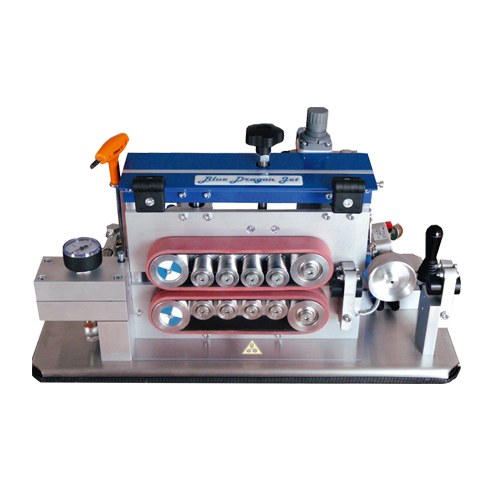

A fiber-blowing equipment piece is a machine that gets specially designed for fitting or uniting the micro ducts into the fiber cables. The medium through which the cable blowing machine joins the ducts can be compressed air or water. It ensures a flawless and consistent joining of fiber cable of the telecommuting ducts. It is an indispensable equipment piece in the telecom and network industry for the application in the establishment phase. It eliminates any gaps or inconsistent parts and allows a flawless connection.

Choosing the one from different options

Why do you think people care so much about the perfect cable-blowing machine? The task of the machine sounds simple as it applies air or water to blow the duct. But there are more than one considerations that one must note. The distinct cable blowers available are for different duct materials and sizes.

Pneumatic and hydraulic cable blowing machines have unique benefits and utilities, even though the end product is similar. But, one needs to recognize the needs and place the order. The variation in the machine is based on the medium in use. The pneumatic blowing machine uses compressed air, and the hydraulic machine uses water as the medium.

Evaluating the machine construction

Besides the medium, the machine parts and design help you recognize the performance aspect. A cable blowing machine is not a single-structured piece of equipment. It contains multiple parts – header, belt feeder, and base frame. The ergonomic design of the machine helps you understand if you can utilize the machine in the specific network. For this, review the challenges in the network and decide prudently.

Reviewing the utility aspect carefully.

Hydraulic and pneumatic fiber blowing machines have distinct mediums. And thus, the functionality differs. A cable blowing machine works with a system of cables through connecting inlets. The connecting surface and setup ensure the efficiency of the setup. Also, the meter counter and monitoring unit determine the accuracy of blowing the medium for duct connection. These are vital aspects that determine the utility and efficiency. Review them to make a sensible call.

Knowing the purpose – Performance, and protection

The utility of blowing machines is high in the industrial sector and among the contractors of the telecommunication service providers. They utilize the blower machine based on the performance of the parts. From the header to the belt feeder - every part must perform optimally to avoid an inconsistent output. Friction reduction is another vital aspect that determines the performance and protection level. Establishing a safe and optimally functioning network is possible when the ducts have a flowless joining.

The new cable-blowing machines ensure better performance and reduce the practical challenges to a large extent. One can find friction-free cable fitting and eliminate the issues of signal interruption.

Things on the priority list – What should you know?

You can find several articles on the internet about the various cable blowing machines and their ratings. But, no one informs you about the indispensable aspects related to these machines. It is vital to know the priority list before choosing the blowing equipment piece. The safety measures are highly crucial; without which one cannot ensure a seamless performance. For instance, lubrication is a vital step and is essential for ensuring optimal performance of the blowing machine. If you are unaware of the lubrication requirements, the chances of misfits and signal interruptions increases. It is a practical step that you must note. Other things to check for better safety practices are –

- The cable condition and the ducts

- The feasibility and utility of the connectors

- Duct size, lubricant quantity, etc.

Knowing the correct steps – Know what matters the most.

A cable blower technician has an in-depth idea about the correct approach to fitting the ducts. They must adapt the fundamental safety drills before using the machine. Even though the ergonomic design of the cable-blowing equipment piece is convenient to use, one needs to stay careful with the accessories. Always test the telecommunication in the different communication centers before running the machine.

Summing note – A branded supplier makes it easy.

Get the cable blowing machine from the right source to ensure zero flaws in the design and optimal utility. Reading the above will help you acquire an overview of what a cable-blowing machine is and the crucial aspects of the functioning of the machine that often go unnoticed.

Popular Tags

-

Cable Blowing Machine

A fiber-blowing equipment

flawless connection

Hydraulic and pneumatic fiber blowing machines

Recent Blogs

- What is the Optical Spectrum Analyzer used for?

- How to choose the right splicing machine?

- How to select and use an OTDR

- What is an oscilloscope? Why is it important?

- What is a Fiber Cable blowing machine? Why is it important?

- What is a RF Spectrum Analyzer & What Does it Do?

- All You Need to Know About Cable and Antenna Analyzer

- Radio Frequency Testing – An Outline About the Basics and More

- An Overall Synopsis of 5G Network Testing

- What makes Insulation Testing such a crucial part of an electrical setup?

- Presenting an Overall Idea About Calibration of pressure instruments

- A Guide To Understand The Concept And Uses Of Master Clock

- Understanding the Role Of Fiber and Copper certifier in Testing

- Know About The Different Optical Test Equipment And Other Factors

- Vital Facts You Must Note About The Different Types Of Electrical Test Equipment

- Essentiality of Master Clocks – All You Need To Know About The Device

- Omni Channel Contact Center Everything You Need To Know About It

- All You Need To Note About OLTS & Ethernet Tester And The Testing Ways

- An Overview of HART Communication Solution And Devices

- Master clocks for Airport – All You Need To Know About The Role Of Time Servers In Airports

- Master clocks for Media Broadcasting Companies – Time Synchronization And Its Need

- Splicing Machines – An Overview Of the Machine And Its Technique